Plastic bonding agent

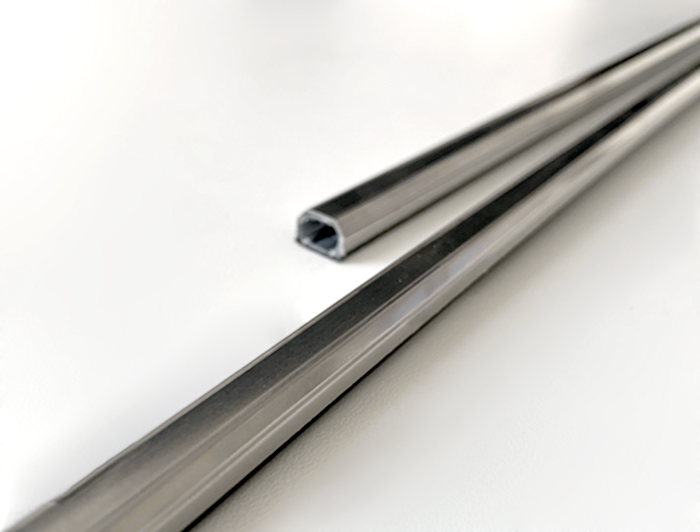

Metal band coatingWithout the use of adhesion promoters, only some plastics are suitable for direct bonding to metal. Our thermoreactive adhesion promoters ensure optimum adhesion between the metal strip and the desired plastic. The achievable adhesion forces depend on the condition of the metal strip (purity; roughness, etc.).

There are two common methods for achieving the required adhesion:

1. by joining the surfaces brought to melting temperature.

2. application of the liquid melt to the adhesion promoter (e.g. back molding, coextrusion)

Carrier material

- Metal types: steel, stainless steel, aluminum, non-ferrous metals

- Coating belt widths/ application widths < 600 mm; can be cut to individual end widths

- Strip thicknesses possible from 0.09 – 2.00 mm depending on the backing material

- Max. Coil weight of 5000 kg

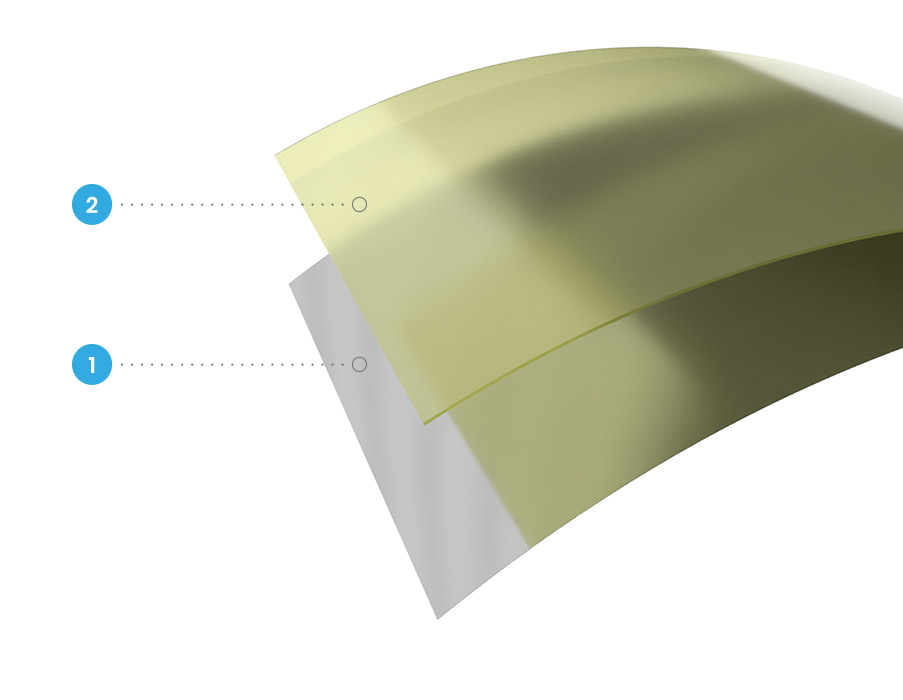

Bonding agent

- We offer a wide range of adhesion promoter systems as 1-layer or 2-layer solutions (primer/topcoat) and ensure optimum adhesion between the plastic and the substrate.

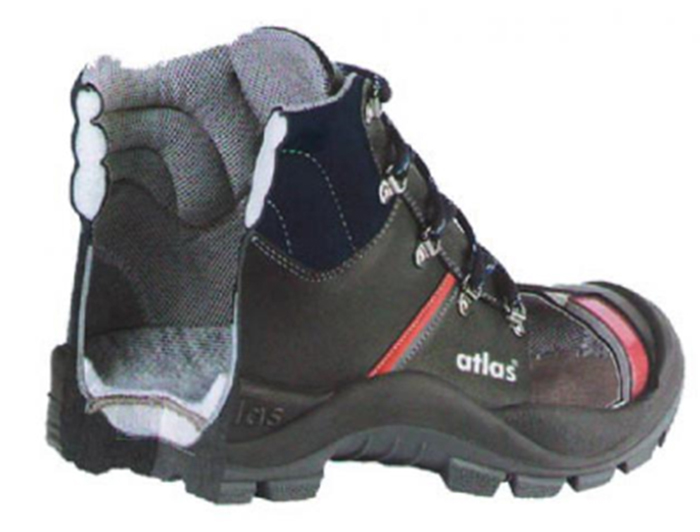

Possible plastic connections

- Polycarbonate (PC)

- Polyvinyl chloride (PVC)

- Acrylonitrile butadiene styrene (ABS)

- Cellulose acetobutyrate (CAB)

- Polypropylene (PP)

- Thermoplastic polyurethane (TPU)

- Polyamide (PA)

- Polyolefines or other thermoplastics

Industry References

Examples from our industry solutions. Based on our wide range of adhesion promoters, we will also find the optimum solution for your application.

Request nowINdIVIDUAL MAnAGEMEnT

More economy

Of course, we will deliver the coated coils in the presentation of your choice. Whether individual single ring packaging with and without cardboard core or wound goods on cardboard core, plastic spools or metal winding racks.

Coiled metal strips

More running lengthIn order to increase the running lengths, we join the metal strips using the latest welding technology and oscillatingly wind them onto new spools. In this way, we reduce set-up and downtimes in your production.

- Strip widths from 1.5 mm up to 60 mm

- Extension of the running length to over 200,000 meters in one core depending on the material

- Individual installation widths from 100 to 400 mm

- Special decoiling racks with winding widths of 800 mm and maximum winding weights of 2,500 kg