We Minimize Friction

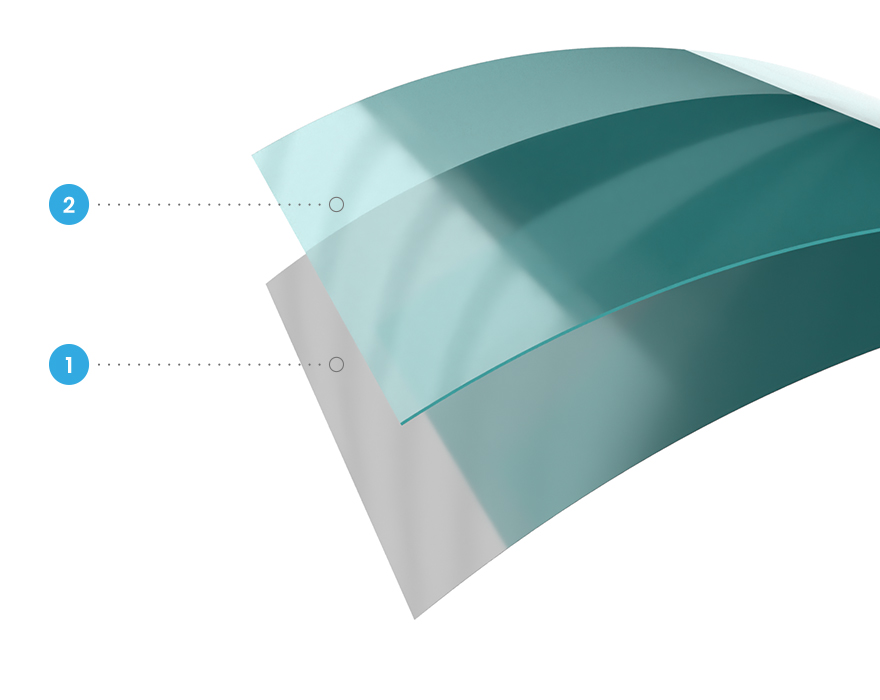

MEtall Coating wiTh Bonded CoatingsThis paint system is primarily used for coating cold-rolled strip steel, but can also be used on other metals. One form of bonded coating is anti-friction coating. This top coat is applied in the final step, for example, to our rubber-coated metal strip and enables special gliding properties of the coated surfaces.

Carrier material

- Metal types: steel, stainless steel, aluminum alloys, non-ferrous metals

- Belt widths of 400-800 mm possible; can be cut to individual end widths

- Tape thicknesses of the carrier material from 0.20-1.00 mm possible

- Max. Coil weight of 8000 kg

Bonded coating

- We offer a wide range of bonded coating systems on various substrates. In our development laboratory, we check to what extent these fit your application, or we develop a special solution for your requirement on this basis.

INdIVIDUAL MAnAGEMEnT

More economy

Of course, we will deliver the coated coils in the presentation of your choice. Whether individual single ring packaging with and without cardboard core or wound goods on cardboard core, plastic spools or metal winding racks.

Coiled metal strips

More running lengthIn order to increase the running lengths, we join the metal strips using the latest welding technology and oscillatingly wind them onto new spools. In this way, we reduce set-up and downtimes in your production.

- Strip widths from 1.5 mm up to 60 mm

- Extension of the running length to over 200,000 meters in one core depending on the material

- Individual installation widths from 100 to 400 mm

- Special decoiling racks with winding widths of 800 mm and maximum winding weights of 2,500 kg